Which are the fastest tyres in the world? — Dugast , no question.

Check out the exotic machines ridden by the world’s top track squads, Australia, France and GB, the common denominator? Dugast.

All the Mavic carbon wheels used by these squads will be shod with the pink tread banded Dugast beauties.

The once dominant Clement silks have disappeared, and only German firm Continental rival the originally French products which are now made in Denekamp, Holland, and even then, Continental supply Dugast with their tyre carcasses.

Dutchman Richard Nieuwhuis is at the helm but founder of the company, Andre Dugast now in his 70s is still involved in the quest for the perfect tubular.

The German national team still run Contis but there has to be suspicion that this is only due to sponsorship obligations.

There are no freebies from Dugast, even world champions (or their Federation) have to pay for them.

In total contrast to the super light low drag track tubulars on display at Manchester World Cups, Dugast also dominate the muddy world of cyclo-cross.

In 2003 at the cross worlds at Monopoli, Italy the Belgian rider Sven Nijs decided he would be better spending his money on new tyres for his camper van, the price being roughly the same as for the Dugasts.

A certain Bart Wellens did not agree and put his Euros down on the counter.

The wiry Belgian rode the tubulars, which had been specifically designed by Nieuwhuis to suit the tree root plagued course, to a puncture free victory.

This year at Pont-Chateau, France all the favourites, including Nijs were on Dugasts.

The Elite podium with Wellens again on the top rung was a Dugast clean sweep.

It almost goes without saying that Nieuwhuis had visited the course personally prior to designing the tyres for the championship.

Interestingly, the fibres used to make the cross tubulars carcass’ are the same as those used for up-market ladies lingerie.

Back to a world devoid of tree roots but still involving wood, in the form of timber slats built in to a steeply banked track.

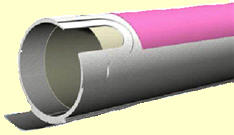

The track tyres are made from natural materials, cotton or silk for the carcass, natural latex for those sexy pink tread bands.

Nieuwhuis recommends cotton for smooth indoor tracks and silk for outdoor tracks where the timber is affected by the weather.

Silk can be used indoors but the already high running pressures, (8-14 bar) should be raised 10%.

The latex tread bands are not vulcanised so are flexible and fast and are only some 15% of the thickness of a normal vulcanised tyres tread band.

The process of vulcanising makes a tyre tougher but slower.

The tread bands are hand glued, using no heat onto the carcass, to save weight the side walls have no protective layer of latex or rubber and must be carefully protected when in transit.

In a match sprint or bunch race a touch of wheels can fatally damage the fragile side walls.

The quality of the raw materials; small numbers of tubulars produced annually (around 2,500 for track use) and the labour intense process mean Dugasts do not come cheap, between €90 and €160 each, but their roll of honour speaks for itself.

One Australian retailer of the product attributes that nations’ track successes solely to the super light tubulars, that is an exaggeration but one thing is sure, come the Olympics this year the bulk of the medals will be won on Dugast.