Founded by its current CEO Blake Pond in 2012, Nopinz is known world-wide as the producer of innovative, aerodynamic cycling kit, both off-the-shelf items such as skinsuits and accessories as well as the famous Nopinz custom kit ranges, widely used by clubs, teams and companies for their training and racing gear.

Here at VeloVeritas we had been looking for a suitable partner for our new cycling and leisure clothing and when we spoke to the folks at Nopinz, based in the south of England in beautiful north Devon, and learned about their offerings, we were very interested and wanted to find out more.

Employed as a flooring and carpet fitter a decade ago and racing on the road and in time trials at a pretty decent level, Blake was always aware of the issues inherent in fixing his race numbers to his skinsuits; the problem of getting the number to be as flat or aero as possible and of course the act of putting pins through expensive wafer-thin lycra, usually resulting in a hole in the material.

It was just such a problem – punching holes in a new, expensive skinsuit on its first wearing in a race – which prompted Blake to come up with the idea of a wallet, or pocket, similar to a “documents enclosed envelope”, which would stick to the rider’s back and hold the race number.

Working on his kitchen table at home, the hurdles Blake faced with the first few iterations of the ‘Speedwallet’ were for it to be stretchy enough to move with the material and with the athlete and also that the adhesive had to be just right; sticky enough to remain in place on the material during the race but easy enough to peel off after the event.

The ‘Speedwallet’ was a success and Blake was able to produce and sell sufficient numbers of them to see the potential. Being a natural innovator he could envisage that making the number pocket a part of the skinsuit rather than just stuck on to it would be a good idea and so the ‘Speedpocket’ evolved, a permanent version of the wallet, it was (and still is) essentially a clear envelope sewn into the skinsuit and eliminating the need for and the hassle of adhesive.

In those early days however, Blake and his small team didn’t have much sewing experience and they worried that folk may not be comfortable sending in their expensive skinsuits to have a hole cut out of it but they needn’t have worried and the idea took hold across the British time trialling scene.

Since Blake’s customers were trusting him with their precious garments it was important that Nopinz had amazing customer service and the company have strived to maintain that standard ever since.

Blake realised that there was a market for skinsuits with the Speedpockets already installed, and for a period of time he bought in pre-made skinsuits, fitted his Speedpockets and sold them as ‘ready to race’, but over time problems with the suppliers such as delivery schedules and minimum order numbers led to the company manufacturing their own skinsuits from start to finish.

First though, ‘Trip Socks’ were an early product; aero socks constructed in such a way as to influence the flow of air around the leg and minimise drag, and Blake partnered with Aerocoach’s Dr Xavier Disley in the development and production of the various versions which were so popular and successful that he was able to purchase the large format dye-sublimation printers, heat presses and additional sewing machines needed to move into producing their own skinsuits in-house. Once fully in control of the process they found they could also innovate and develop new products very quickly.

Ex-professional rider and top time triallist Marcin Bialoblocki helped develop the product lines, his exacting standards and attention to detail making the difference in fine-tuning the garments.

By this time the ‘Speedpocket’ and Nopinz’ other innovations had changed the thinking across the cycling world, all the way to the top of the sport and the World Tour teams competing in the Tour de France, with several teams using Nopinz products often rebranded to bear the name of their clothing sponsor.

Most top end clothing manufacturers are now involved in similar approaches to Nopinz and the ‘Speedpocket’; several of them do the right thing and buy the ‘Speedpockets’ from Nopinz to install into their own skinsuits and speedsuits but some others don’t and have come up with their own very similar versions, despite the patents applied to Blake’s design.

We’ve partnered with Nopinz to produce our fantastic VeloVeritas kit and we were lucky enough to be able to visit the factory in Devon recently to see the first batch of our own kit being put through the production process, from the design planning, cloth being printed to the kit being sewn together.

We were hosted for the day by ex-British 30 mile TT Record holder and Nopinz’ Sales Director Gary Chambers, who we interviewed back in March, and Blake also gave us a good chunk of his time (and bought us lunch).

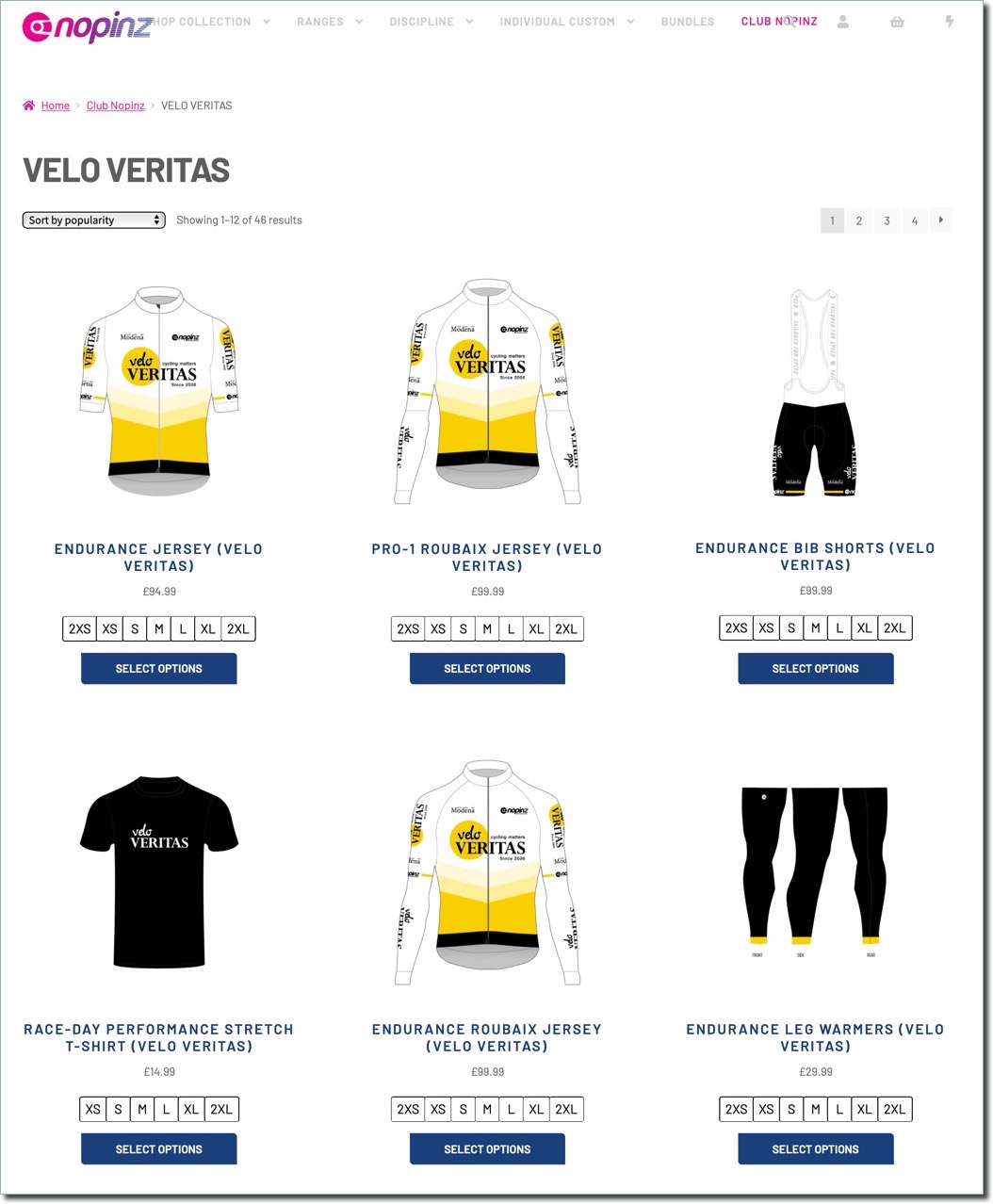

Gary explained that the custom cycling clothing business has grown phenomenally for the company, and now they have around 500 clubs, organisations and teams worldwide maintaining a ‘kit shop’, which collectively is called ‘Club Nopinz‘.

With an average of 46 items available in a club’s kit shop there are over 1,300 kit options per club (ie. male/female, sizes going from 2XS through to 2XL, as well as Standard/Tall configuration…) it takes a lot of organisation to fulfill such a vast array of permutations.

We were interested to see just what happens once your order is placed through the Club shop and how your design is turned into fabulous garments so read on to discover what we learned about the Nopinz custom kit manufacturing process.

Contents

- The Nopinz Custom Kit Process

- Step 1 – you start the ball rolling

- Step 2 – work with your designer to nail down your design

- Step 3 – your club shop is setup

- Step 4 – the design is positioned onto the template flats

- Step 5 – your club shop is now open!

- Step 6 – the flats are setup and scheduled for printing

- Step 7 – the flats are printed

- Step 8 – the flat designs are transferred onto the fabric panels

- Step 9 – the cloth panels are cut out

- Step 10 – panels for each garment are collated

- Step 11 – the panels are sewn together to create the garment

- Step 12 – your order is assembled and posted to you!

- How does the Nopinz Custom kit turn out?

- Indoor Cycling

- Nopinz Custom Kit – Made to Measure

- Nopinz Custom Kit – Top Tips

* * *

The Nopinz Custom Kit Process

Step 1 – you start the ball rolling

There are a number of ways to get in touch with the folks at Nopinz to get started. You can contact them through their on-line form, you can email them using administration@nopinz.com or you can call them on 01271 859573.

If you reckon you’re going to go with Nopinz for your custom kit you simply purchase a club shop setup. The initial setup fee for this is £100.

Once you’ve kicked things off, the in-house design team will contact you via the email address you used to purchase the club shop.

You should have your design brief ready to pass to the team, along with any artwork / logos you wish to be used and these files should preferably be in vector format or a high resolution file. A vector file can be Ai, EPS or PDF, if you don’t have your files in this format there may be a small charge for converting them.

* * *

Step 2 – work with your designer to nail down your design

The designer assigned to work with you will get in touch to discuss the work and answer any questions you may have, working iteratively with you until you and they have nailed down the design.

We worked with our designer Toby to get the kit we envisioned ready for the next stage. Toby was fantastic at replying to our emails quickly and he proactively asked questions about, for example, the colour of the zip guards and tweaking things like the shades of yellow and the size of the various logos.

There is no limit to the number of iterations that can be made during the design process (just as well really since we took a bit of time working with Toby to get the upper shades of yellow on our jersey design perfected) and the design team will continue to work with you until you’re completely happy with your new kit design.

Once you’re happy with everything you will be required to ‘sign off’ on the design so it’s worth noting that any design changes after this point will require another design fee.

* * *

Step 3 – your club shop is setup

Your club shop can now be created and once ready you will be provided with the link to it, and a unique access code (password) will be provided if you want your shop to have restricted access. You can leave your shop ‘open’ if you want, which is what we’ve done with our VeloVeritas kit shop.

Once your club designs are approved, they are uploaded to your club shop, and you can choose to provide only a narrow set of items from the various ranges or offer all the items for sale in your shop.

Your club and members can now log into their club shop 24/7 and enjoy ordering club kit with no minimum orders, straight to their doorstep.

* * *

Step 4 – the design is positioned onto the template flats

Next, the design and logos are placed onto the ‘flats’, or panel templates, in readiness for printing.

The flats are ‘graded’, or scaled, meaning that whatever the size of the garment being produced the artwork stays the same size, so a logo on an XL jersey will be the same relative size on a smaller jersey.

These ‘graded’ design flats are saved to a database which helps to make the production process very efficient because the printing can be automatically scheduled when an item is ordered through the club shop website.

* * *

Step 5 – your club shop is now open!

You and your club mates can now create an account on Nopinz.com (which makes it easier to reorder items and follow the progress of your order, but you don’t have to) and purchase the items you wish, from one pair of socks to a fully customised aero flow suit, and all the kit you need in between.

* * *

Step 6 – the flats are setup and scheduled for printing

Since the panels on the clothing are different sizes and shapes, a run of cloth is setup to minimise waste, a bit like the Tetris computer game; fitting as many items from orders reaching the printing stage and from different clubs as possible, all of which need to use the same fabric.

Clearly then, the scheduling of club prints is important. Production Manager Jess coordinates the workload across the Designers, the Printers/Cutters and the Machinists.

Bespoke garments such as the Custom-Fit Flow-Suit which are unique to the customer have the logos designed, scaled and positioned by Katie.

* * *

Step 7 – the flats are printed

The print run for the particular items requiring the specific fabric is scheduled.

First of all the flats are printed onto dye sublimation ‘textile transfer’ paper. This special heat transfer paper is used with sublimation ink and when it’s printed it looks a little ‘washed out’ but once the ink is transformed (ie. heat-transferred onto the fabric) it’s very clear, dark and sharp.

One-off items can be sent through a different printer on their own if necessary, rather than being part of a larger job with many different clubs designs and item parts. This might be because of an urgent order, for example for a new World Champion’s time trial skinsuit.

White fabrics are used for the printed, coloured items and the design graphics are printed in reverse onto the paper.

Black fabrics are used for base colours and items which don’t need to have any printing, such as the main panels on shorts, or black garments.

There are various materials and fabrics all kept in stock to ensure an unbroken manufacturing process.

Each fabric is used in focused areas of the garment following extensive wind tunnel testing, and are all specific to purpose, such as the slightly ribbed ‘Pista’ fabric on sleeves and other areas, careful positioning of trip seams and Nopinz’ own proprietary super-sleek fabric ‘Speedscalez’ on larger panels – and of course the finished garments fully conform to UCI standards.

* * *

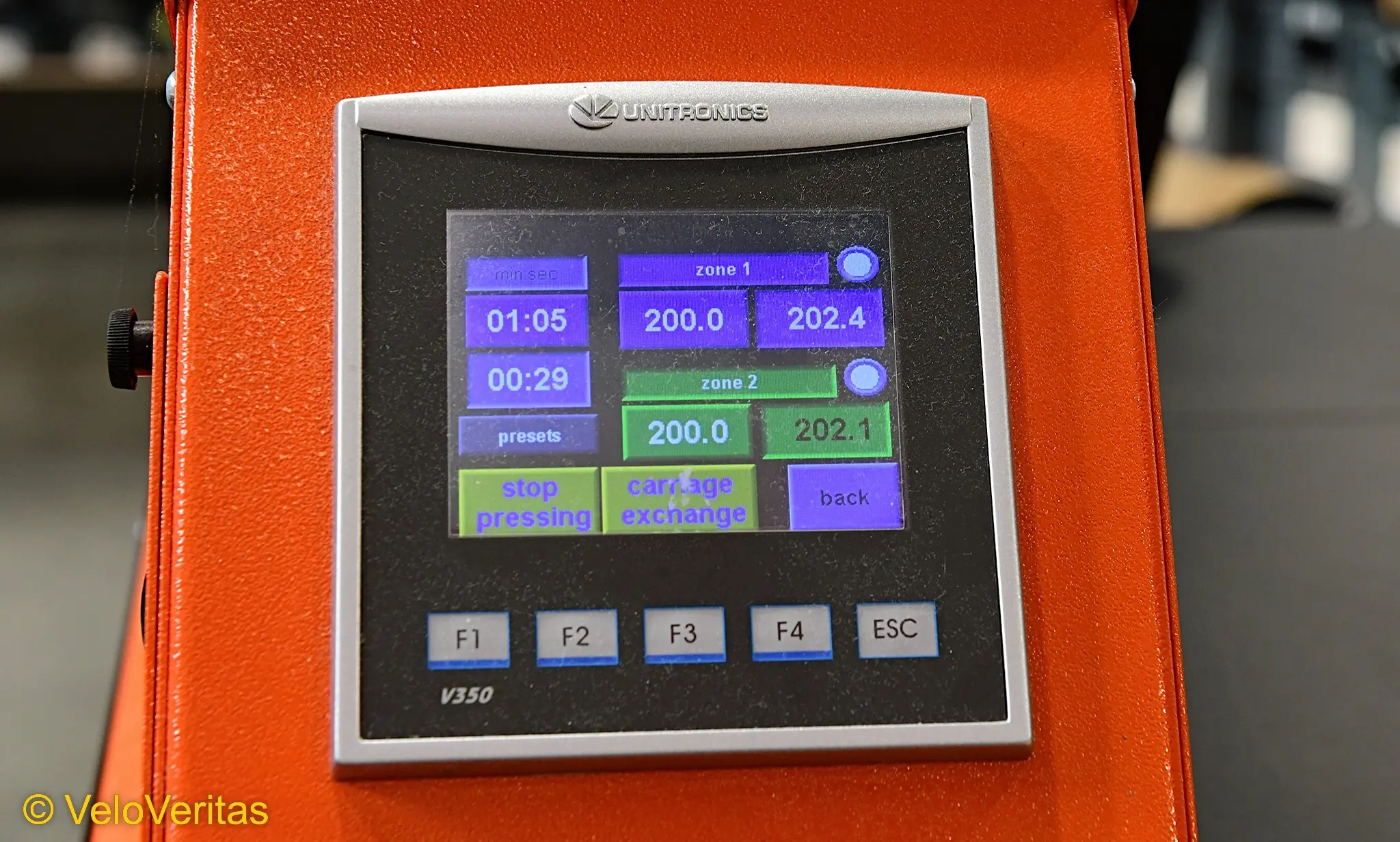

Step 8 – the flat designs are transferred onto the fabric panels

The dye sublimation ‘textile transfer’ paper is placed onto the appropriate fabric and is heat-pressed at a low rate but a very high temperature to ensure the design retains its sharp lines and edges.

* * *

Step 9 – the cloth panels are cut out

The edges of the fabric are cut out by laser, pin-point guided using the pre-programmed black outlines of the design.

Sometimes, for one-off kit such as late high priority requests and very small runs, the cloth is cut by hand. The guys make this look easy but it’s quite a skill.

* * *

Step 10 – panels for each garment are collated

All the pieces required to construct the garment are placed together in a bag so the machinist has all the parts needed when sewing the garment together.

* * *

Step 11 – the panels are sewn together to create the garment

The machinist then sews the garment together which is a tricky business when working with stretchy lycra, seatpads, and tight tolerances.

The zip guards are added, silicon grippers are applied and the item is quality checked and bagged.

The machinist signs-off on each item they produce and adds their name on the hang tag.

* * *

Step 12 – your order is assembled and posted to you!

Once the order is complete your Nopinz custom kit is posted out to you. No club ‘kit secretary’ needed. You’ll receive an email to let you know it’s on its way.

* * *

How does the Nopinz Custom kit turn out?

We’re really happy with our Nopinz custom kit, how it well it is made, how it looks and how it rides; we think it’s fabulous.

The kit is as good as anything we’ve used before, and I mean both mass-produced top end clothing by famous Swiss and Italian brands as well as custom made kit by names you know and which supply the world’s biggest races with leader’s jerseys and speedsuits.

World Tour teams know how comfortable and – more importantly for them – how fast the kit is and plenty of them have used Nopinz clothing in the top races, including the recent Tour de France.

Our custom kit is great looking, the quality of the materials and fabrics used is obvious and the fit is exactly what’s needed.

The Pro-1 range items are very tight yet still comfortable, fitted in exactly the right way for fast riding and racing – it’s hard to see where the aero improvements are going to be found after this.

It’s all been tested in the wind-tunnel and sometimes the Nopinz guys will go into the wind tunnel just to try out some ideas, occasionaly with surprising results; for example like finding that a certain short sleeved design saved a surprisingly large number of watts when compared with a long sleeved suit.

The Pro-1 range has been developed with one aim; affordable performance. The range consists of everything you need to go fast both in racing and in training and it’s perfectly suited for serious racers looking to maximise their performance and getting from A to B with minimum effort and in maximum comfort thanks to the ‘Pista’ fabric on the arms making it super-slippy and the massively breathable ‘Chrono’ fabric on the torso that keeps things dry and cool.

The Pro-1 range includes items such as road skinsuits, all season (cross) skinsuits, speed suits, bib shorts and long and short sleeved jerseys, and feature an aggressive race cut which is designed to fit you when in position on the bike and not when in the café queue.

The Endurance range jerseys and shorts are what I would term ‘top-quality club kit’ – they are a bit more of a relaxed fit compared to the Pro-1 range and will be perfect for most riding requirements.

The lower half items (bib tights and shorts) have the same fit as the Pro 1 range but feature improved longevity with solid fabric on the front and rear crotch areas to prevent wear.

The Endurance range includes short and long sleeved jerseys, bib-shorts and bib-tights, and leg warmers. Made entirely from Italian high wicking, breathable and four-way stretch fabric.

It was clear the attention to detail and the personal ownership the various folk involved in the company took, the feeling we noticed during our visit was one of a relatively small, friendly, welcoming group of people who took their jobs very seriously and who maintained the customer at the heart of what they do – we heard several stories about how last-minute requests, unique order designs and emergency crash replacements always arrived at the worst possible time but were sorted out as priorities; the staff pulling out all the stops to meet deadlines and expectations.

* * *

Indoor Cycling

Nopinz reckon that their indoor-specific kit, the Sub-Zero range is the world’s best indoor-specific clothing, designed for riders who take their e-racing and training seriously.

The Sub-Zero race suit has been specifically designed for e-racing where live streaming requires a top to be worn.

‘FreezePockets’ are located in the upper-mid and lower back area to actively reduce core temperature, allowing you to perform at your best for longer.

The cooling packs (purchased separately) are interchangeable and can be easily swapped during your session to maintain the cooling advantage – each set is available with two sets of gel packs to give 40-60 mins of cooling at high intensity.

The range includes the Sub-Zero skinsuit, jersey and bibshorts and uses ultra-lightweight and breathable fabrics which add to the cooling effect. The seatpad is also optimized for indoor riding and offers extra protection with improved moisture management compared to those in standard bibs.

* * *

Nopinz Custom Kit – Made to Measure

We’ve mentioned the made-to-measure option in this article a few times; the Custom-Fit service allows you to get a perfect no-compromise fit, further enhancing both comfort and performance.

You simply fill in and submit the form (male and female versions) with your own measurements or you can of course present yourself at the Nopinz factory in Barnstaple, UK for full, World Tour-level 3D body scanning – and, using these measurements Nopinz will customise the fit of the garment specifically and exactly for you to create the perfect fit.

The measurements are used to create a virtual avatar onto which the various kit panels are placed together, after being sized appropriately (see Step 6, above).

Blake and Gary have taken the body scanning equipment to various World Tour teams’ training camps and you’ll see the top riders wearing Nopinz skinsuits in Grand Tour time trials and road stages – you just won’t realise it because they’re branded in the team’s usual kit supplier’s logos.

GCN’s Ollie Bridgewood used a custom Nopinz skinsuit to save loads of watts. Have a look at this video where Ollie explains the custom process in detail;

* * *

Nopinz Custom Kit – Top Tips

- Don’t leave it until March to think about your clothing requirements for the season.

- Don’t leave it until November to think about your requirements for the winter, training and racing ‘cross.

- Start the process yourself by contacting Nopinz through their site and sign up to Club Nopinz.

- Make sure you use their up-to-date sizing charts, and pay attention to the characteristics of the various ranges.

- If you’re between sizes and are buying a Pro-1 garment, go up a size.

- If you want to organise you club kit the ‘old school way’ using a ‘kit secretary’ to coordinate everyone’s requirements and orders, you can contact Nopinz and arrange all the various items that way. One upside is that a bulk discount may be available but the downsides are well known to kit secretaries for a long time; gathering folks’ choices, all the various sizes – and the money… then distributing all the kit to the right owners once it’s delivered and dealing with the ‘feedback’.

Why not start by having a look around the VeloVeritas club shop?

Note: we paid for our VeloVeritas Nopinz kit in the regular way described in this article.