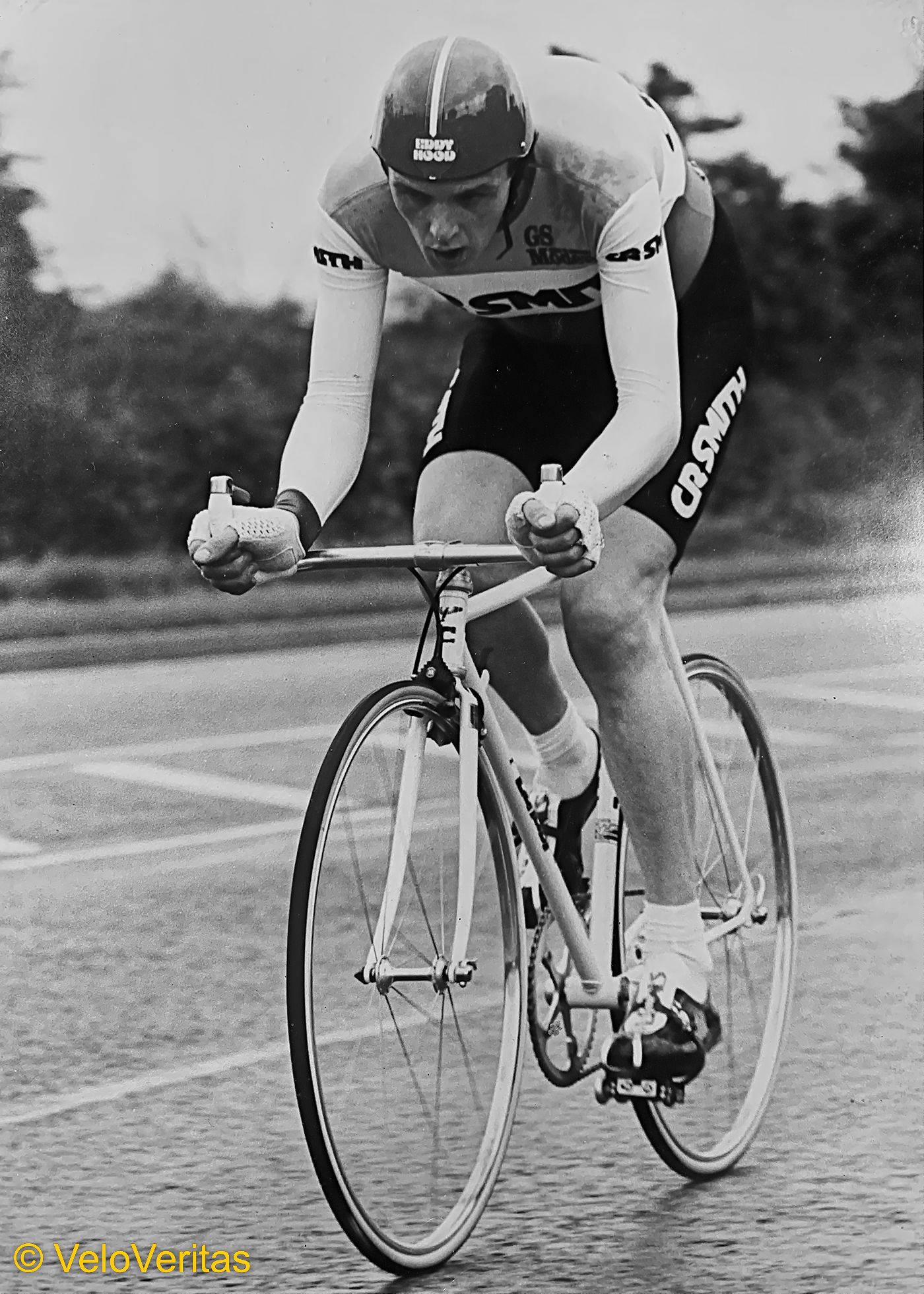

I loved my 1970’s Shorter, ‘Alf Engers replica’ time trial bike; but things were changing, drilling was no longer the road to travel – the world had gone ‘lo pro.’

By the 80’s then it was time to move on and the pilgrimage was duly undertaken to the hallowed surroundings of Condor Cycles in London, with my mentor Stewart Sutherland – a devoted ‘Condor Man’, and our buddy John Montgomery.

Notoriously grumpy ex-pro – and winner of two Six Day races, London and Montreal – Tony Gowland was behind the counter and a young guy was trying to buy a 12 sprocket for his freewheel;

“Look son, there are about six guys in the whole of Britain can turn one of those – and you’re not one of them!”

Tony explained to the disillusioned youngster.

Fortunately, my rendezvous was with Condor founder and bicycle construction royalty, the late Monty Young who among others had built frames for World Professional Pursuit Champion, Hugh Porter, Six Day star, Graeme Gilmore and top British time tester, John Pritchard.

Stewart had drawn the frame up based on my position on the Shorter and after a long consultation with an incredibly knowledgeable and patient Monty, the frame was ordered.

It was built by legendary builder Vic Edwards in a small workshop in Crow Lane, Romford, Essex – he also built frames under his own ‘Rondinella’ [Italian for ‘swallow’] marque – and they were gems.

Mine was constructed from Reynolds 753 – which the tube manufacturer wouldn’t sell to just any builder; potential customers had to do a test and if they passed they gained certification from Reynolds, which allowed them to buy the tubes.

Lugs had to be silver soldered with 753 and on my frame they were filed right back, clearances were tight with the rear drop-outs facing back to enable the rear wheel to tuck tight against the seat tube.

Starting at the top, my derriere perched upon a Saba superlight saddle which sat atop a Shimano Dura Ace seat pillar which looked ‘kinda aero’ – we were just beginning to get into all that, back then.

Originally I had a ‘flat’ handlebar extension of Japanese origin which I can’t remember but eventually went for a longer, sloping Cinelli 1a stem which gave me a better position.

The expander and pinch bolts were Saba super-light substitutions.

Handlebars were inverted and chopped Cinelli 66 with internal cable routing, originally I had Campagnolo handlebar gear control levers operating the brakes but changed to Suntour levers.

The rules stated that you had to have two independently operable brakes on the bike but didn’t stipulate that you had have one at the front and one at the back so I had both brakes on the front crown – a beautiful but hopelessly ineffectual Modolo Kronos on the front and a ‘chopped’ Weinmann 500 on a brazed-on spigot behind the crown.

Slowing down was always interesting, verging on impossible with the handlebar control levers.

The gear lever – to a boss on top of the down tube, with the gear cable concealed inside the frame – was originally a Saba resin job but they kept breaking so I fitted a filed and polished Campagnolo lever.

The rear mechanism was a super-light Huret ‘Jubilee.’

These had been fitted to the Raleigh ‘Euro Team’ bikes back in the early 70’s but within weeks the pictures in the ‘Cycling Weekly’ magazine revealed that the team members were fitting their own Campagnolo rear mechanisms – the Jubilee simply not up to the rigours of north European professional bike racing – they were fine for a 10 mile time trial though…

The bottom bracket was a Campagnolo titanium number which required careful fitting and adjustment because the cups were so ‘soft,’ the end bolts and chainring fixing bolts were all replacement, light alloy Saba components.

Cranks were beautiful Campagnolo 177.5 mm ‘Pistas’ with Campagnolo ‘black track’ pedals Christophe alloy toe clips and toe straps, the latter having alloy buckles.

I always ran Sedis chains because there were never any problems with them meshing with an ‘alien’ freewheel.

Tubulars were by Wolber; 16mm section on Assos ‘aero’ rims with bladed, radial, stainless spokes; small flange hubs – with dust caps removed and lubed with Teflon spray – were by Campagnolo with titanium replacement spindles – you had to set these up so that they were slightly ‘lose’ before you engaged the quick release because the ‘soft’ titanium axles compressed when you clamped them.

The skewer adjusters were again by Saba, in black alloy.

A six speed Maillard alloy 12 up freewheel with a 57 tooth Campagnolo chain ring completed the spec.

But that was the 80’s and this is 2021.

There have been a lot of years with no serious cycling and a touch of Spinal Stenosis hasn’t helped things with even the ride to the paper shop on the ‘fixie’ hard work on the little climb out of the village.

But being as obsessed as I am with bicycles and bike racing I missed being out in the countryside on a nice machine, so much.

What to do?

The majority of the electric bikes I checked out had all manner of lumps bumps and protuberances and were simply not ‘cred’ – I may be old and not as slender as I was but I still have to look the part.

The ‘Eureka’ moment came when I saw a picture of Sean Yates astride a Ribble ‘e’ bike.

Not a lump, bump or protuberance to be seen.

How come?

The battery is inside the down tube and the motor is in the rear hub; to all but the most knowledgeable observer it looked just like any modern road machine.

But there’s the thing – a ‘road machine’. I live on the Fife Coastal Path and have a notion to ride the off-road, ‘Pilgrims Way’ from lovely Culross to beautiful Saint Andrews.

I therefore duly confess then… I’ve ‘gone gravel’.

I know what you’re thinking, ‘your curmudgeon mentor, Vik isn’t going to like that!’

An ‘e’ gravel bike with disc brakes – yes, that’s gonna be a difficult conversation…

Barney’s spec. (you know, Barney Ribble/Barney Rubble?) is a little different from the Condor.

It’s a Ribble Gravel AL e – Pro; the frame is 6061-T6 aluminium with a carbon fork and LEVEL 56 headset.

The groupset is the Shimano top-of-the-range cable operated GRX RX 810 with 1 x 11 transmission and flat mount GRX hydraulic discs.

The chain is by famous Japanese specialists, KMC.

The saddle is a Fizik Taiga S-Alloy Rails on a Level 3 Inline 27.2 mm Carbon Monocoque seat post.

Handlebars and extension are by LEVEL clad with LEVEL tape.

Wheels are Mavic Allroad 650b DCL shod with WTB Sendero rubber.

We’ll not get into the weight here, suffice to say it’s around twice what the Condor was, but then all the watts going through the drivetrain on the Condor were down to yours truly.

Whilst the Ribble blurb tells me;

“A sleek and lightweight MAHLE SmartBike Systems X35+ hub drive motor and a Panasonic 250Wh battery hidden within the frames downtube provides up to 250W of assistance to each pedal stroke, all at the press of a button.

“The extra assistance feels as natural as a non-powered gravel bike and will help you to effortlessly navigate the toughest off-road terrain or conquer any climb.”

That’ll do for me!

What’s that?

How do the bottom gears compare?

Well, the Condor’s was 57 x 17 and Barney’s is 40 x 40. But it’s 33 years since last I rode the Condor.

How does Barney ride?

Watch this space…